◆結構與工作原理

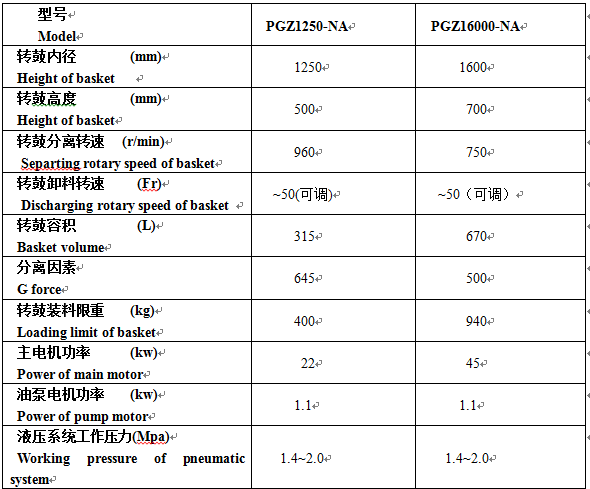

PGZ系列平板式離心機為間隙式周期性工作方式的離心機。它在可編程序的控制下,由電氣系統自動完成工作周期。可實現多次進料、多次洗滌、多次脫水的要求。采用變頻調速電機,及其各階段轉速可根據需要進行任意調節。其工序和時間可通過調整程序而隨意調整,工作程序分為七個工序:1.轉鼓啟動;2.進料;3.脫水;4.洗料5.二次脫水;6.轉鼓制動至低速;7.卸料,以達到最佳工作效率。

PGZ系列(lie)平板離心機(ji)是(shi)一(yi)種全自動控(kong)(kong)制(zhi)的(de)(de)立式刮(gua)刀(dao)(dao)卸(xie)料(liao)(liao)(liao)離心機(ji),在(zai)(zai)電(dian)氣控(kong)(kong)制(zhi)下(xia),轉(zhuan)(zhuan)(zhuan)(zhuan)鼓(gu)(gu)(gu)(gu)(gu)啟(qi)動達到(dao)(dao)(dao)進(jin)料(liao)(liao)(liao)速(su)度(du)后(hou)(hou),控(kong)(kong)制(zhi)系統打開進(jin)料(liao)(liao)(liao)閥(fa),被處理懸浮(fu)液(ye)(ye)(ye)從(cong)進(jin)料(liao)(liao)(liao)管進(jin)入轉(zhuan)(zhuan)(zhuan)(zhuan)鼓(gu)(gu)(gu)(gu)(gu)。在(zai)(zai)轉(zhuan)(zhuan)(zhuan)(zhuan)鼓(gu)(gu)(gu)(gu)(gu)高(gao)速(su)旋(xuan)轉(zhuan)(zhuan)(zhuan)(zhuan)產生的(de)(de)強大離心機(ji)作(zuo)用下(xia),進(jin)入轉(zhuan)(zhuan)(zhuan)(zhuan)鼓(gu)(gu)(gu)(gu)(gu)內的(de)(de)懸浮(fu)液(ye)(ye)(ye)被均勻布于(yu)轉(zhuan)(zhuan)(zhuan)(zhuan)鼓(gu)(gu)(gu)(gu)(gu)內壁(bi)(bi)的(de)(de)過(guo)濾介質上,成(cheng)空心圓(yuan)柱狀(zhuang)。液(ye)(ye)(ye)相(xiang)通過(guo)過(guo)濾介質和轉(zhuan)(zhuan)(zhuan)(zhuan)鼓(gu)(gu)(gu)(gu)(gu)上的(de)(de)許多小孔被甩出轉(zhuan)(zhuan)(zhuan)(zhuan)鼓(gu)(gu)(gu)(gu)(gu)外,由機(ji)殼(ke)內壁(bi)(bi)和底(di)盤(pan)搜集,從(cong)出液(ye)(ye)(ye)管排(pai)除(chu),而固(gu)相(xiang)粒子則(ze)被留在(zai)(zai)過(guo)濾介質上。當(dang)進(jin)料(liao)(liao)(liao)量達到(dao)(dao)(dao)設定(ding)值,由料(liao)(liao)(liao)層控(kong)(kong)制(zhi)器(或進(jin)料(liao)(liao)(liao)時(shi)間)向控(kong)(kong)制(zhi)系統發出信號(hao),關(guan)閉(bi)進(jin)料(liao)(liao)(liao)閥(fa)門。同時(shi),根(gen)據(ju)工藝需要(yao)(yao)可對物(wu)料(liao)(liao)(liao)進(jin)行洗滌,洗滌達到(dao)(dao)(dao)要(yao)(yao)求后(hou)(hou),在(zai)(zai)脫(tuo)水速(su)度(du)下(xia)進(jin)行二(er)次脫(tuo)水。處理物(wu)料(liao)(liao)(liao)達到(dao)(dao)(dao)分離要(yao)(yao)求,控(kong)(kong)制(zhi)系統控(kong)(kong)制(zhi)主電(dian)機(ji)將回轉(zhuan)(zhuan)(zhuan)(zhuan)體的(de)(de)轉(zhuan)(zhuan)(zhuan)(zhuan)速(su)降到(dao)(dao)(dao)卸(xie)料(liao)(liao)(liao)速(su)度(du),卸(xie)料(liao)(liao)(liao)機(ji)構(gou)采(cai)用窄刮(gua)刀(dao)(dao),先由旋(xuan)轉(zhuan)(zhuan)(zhuan)(zhuan)缸驅動徑向刮(gua)料(liao)(liao)(liao),到(dao)(dao)(dao)位后(hou)(hou)停留一(yi)下(xia),在(zai)(zai)軸向行程卸(xie)料(liao)(liao)(liao),下(xia)降到(dao)(dao)(dao)位刮(gua)刀(dao)(dao)下(xia)轉(zhuan)(zhuan)(zhuan)(zhuan)鼓(gu)(gu)(gu)(gu)(gu)上的(de)(de)物(wu)料(liao)(liao)(liao)。固(gu)相(xiang)顆粒通過(guo)刮(gua)刀(dao)(dao)卸(xie)料(liao)(liao)(liao)借助重(zhong)力經過(guo)轉(zhuan)(zhuan)(zhuan)(zhuan)鼓(gu)(gu)(gu)(gu)(gu)底(di)的(de)(de)卸(xie)料(liao)(liao)(liao)口從(cong)基座(zuo)底(di)部排(pai)除(chu)。機(ji)器完(wan)成(cheng)一(yi)個工作(zuo)循(xun)環(huan),在(zai)(zai)控(kong)(kong)制(zhi)系統(PLC)的(de)(de)控(kong)(kong)制(zhi)下(xia)進(jin)入到(dao)(dao)(dao)下(xia)一(yi)個工作(zuo)循(xun)環(huan)。

技術支持:

技術支持: